Emergency power supply for permanent conveyor system closures

Necessity for emergency power supply

General

The guidelines for hold open systems of the German Institute for

Construction (DIBT) describe the design of control units for conveyor system

closures. According to these guideslines it has to be assured that the closing

area is free of any conveyed goods with closures that are held open by these

devices.

Specific for conveyor system closures

Conveyor systems that pass through closing areas are driven in most

cases with electrical energy. In case of power failure the closing area has

nevertheless to be cleared in case of release (fire alarm). The control unit

for the hold open device must have an uninterrupted power supply of 24VDC to

hold the closure open while the clearing process also in case of power failure.

Appropriate measures

- with standing conveyor technique: clearing device resp. clearing systems

- with continuing conveyor technique: emergency power supply

Due to the different kinds of conveyor systems (belt conveyor, roller

conveyor, chain conveyor, circular conveyor or mono rail conveyors) we adapt

our emergency power supply to the conveyor system.

Functional principle

1 grid provided on site:

The switchover - provided on site - between the normal and emergency power takes place in front of the cabinet of the central resp. decentralized clearance control unit. The order of the clearing processes is driven by the control unit of hold open system.

2 grids provided on site:

The switchover between the normal and emergency power takes place in the cabinet of the central clearance control unit by the control unit from Stöbich. The order of the clearing processes is defined by the control unit of the hold open system and the clearance sequence control unit.

Calculation of the Powerdrive performance:

Performance Powerdrive = Sum of the single performances of the motors of one conveyor track that has to be driven at the same time.

Versions emergency power

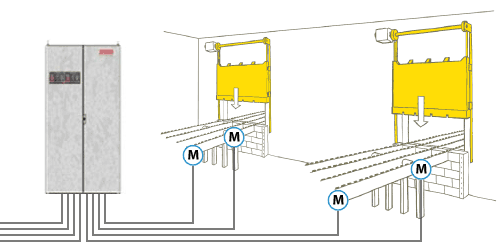

1. Decentralized emergency power

Functional principle: The emergency power supply and the clearance control unit are installed directly in front of the motors of the conveyor systems. It is possible to drive one or more conveyor tracks right next to the closures in case of release.

|

Motor cable

|

|

Emergency power supply wiring |

|

Emergency power |

Decentralized emergency power supply „Powerdrive“

2. Central emergency power

Functional principle: The emergency power supply and the clearance control unit are mounted in a central cabinet. All cables of the conveyor tracks are pulled over the central cabinet.

| Motor cable of the cabinet of the conveyor technique |

|

Central emergency power supply with hold open system control unit